At Ecscell we provide flow battery hardware with flexible cell designs to study the influence of electrode, electrolyte and channel configurations on flow battery performance, help to design better flow batteries and identify optimal operating strategies.

The promise of Redox Flow Batteries (RFBs) utilizing soluble redox couples is becoming recognized for large-scale energy storage. Flow batteries offer a unique solution to grid-scale energy storage because of their electrolyte tanks which allow easy scaling of storage capacity. As energy-intensive storage systems can support integration of intermittent renewable, such as solar and wind, into the grid, the scalability of RFB systems presents an economic opportunity.

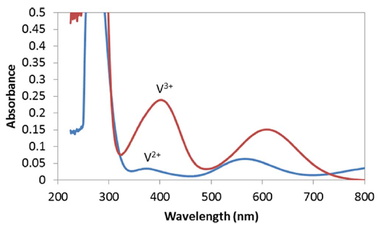

Although many types of RFBs are being explored, the all Vanadium RFB (VRFB) has been most widely researched and appears to be the closest to broad commercial implementation.

Although many types of RFBs are being explored, the all Vanadium RFB (VRFB) has been most widely researched and appears to be the closest to broad commercial implementation.

|

Related RFB research areas that seek to increase energy density and/or employ inexpensive electrolytes, such as nonaqueous systems, bromine, sulfur, and iron-based chemistries, generally focus on development of materials that overcome cell voltage and the cost of vanadium. The composition of this electrolyte impacts the hydraulic, kinetic, ohmic, and mass-transfer resistances, as well as the system stability.

|

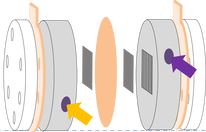

Membrane is a critical component of redox flow batteries as it determines the performance as well as the economic viability of the batterie. The membrane acts as a separator to prevent cross-mixing of the positive and negative electrolytes, while allowing the transport of ions to complete the circuit. An ideal membrane should have high ionic conductivity, excellent chemical and thermal stability as well as good ionic exchange capacity.

One of ongoing efforts associated with these RFBs is determining whether the developed soluble redox couples is suitable and competitive for large-scale energy storage.

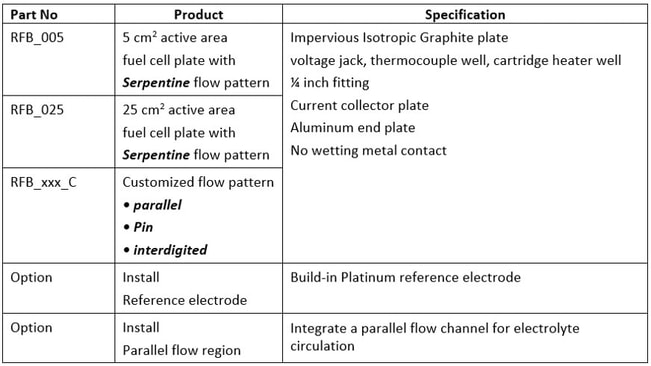

Ecscell offers flow batteries with graphite material and without wetting metal contact.

One of ongoing efforts associated with these RFBs is determining whether the developed soluble redox couples is suitable and competitive for large-scale energy storage.

Ecscell offers flow batteries with graphite material and without wetting metal contact.

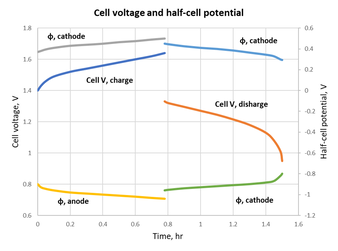

- Ecscell’s cell is equipped with dual reference electrodes or reversible hydrogen electrode (RHE) incorporated into the catholye and anolyte circuits to monitor the cathodic and anodic half-cell potential.

- Ecscell’s cell is equipped with one parallel flow region which allows collect ions that diffuse from the positive and negative half cells, measuring ion crossover and diffusion coefficients.

Flow Battery

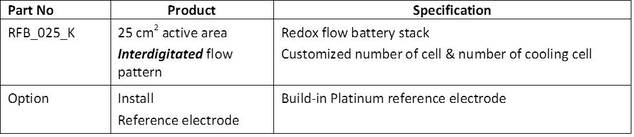

Designed to allow the build of multi-cell stack and built-in cooling plate

Features

- Easy open, easy close

- Leak-proof construction

- Interdigitated flow field giving low pressure drop at high mass transport

- Tighten rod going through all the components enables uniform compression

- Precision gaskets as a seal that pinch is optimized to achieve sufficient compression

- No wetting metal contact; eliminate acidic corrosion

- Designed with temperature sensor and heater

- Cooling plate is available as option

- Reference electrode/parallel flow region can be installed as option

Applications

|

|

Part Number

|

Product

|

Specification

|

|

Graphitized carbon felt

|

PAN-based graphite felts (3.2 mm)

|

|

Polymer Electrolyte Membrane

|

Nafion membrane

Cation exchange membrane (CEM) Anion exchange membrane (AEM) |

|

EPDM Gasket

|

Precision flat gasket

|

|

872-216-7641

|

Ecscell.com

|