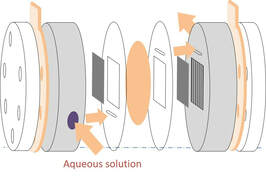

Ecscell Capacitive Deionization (CDI) cell hardware is designed to meet the demands of a wide variety of electrochemical capacitive deionization process.

|

Capacitive Deionization (CDI) is an emerging technology for the removal of charged ionic species from aqueous solutions and has been widely explored for water desalination applications. The technology is based on reversible salt adsorption–desorption at porous carbon electrodes. To achieve optimal desalination, CDI electrodes would possess high electrical conductivity, large surface area, good wettability and porous structure for ion and electron transportation.

|

|

Ecscell designs CDI with unique features and functionalities

|

Ecscell offers CDI hardware with flow electrode and static electrode cell architectures

Features

|

Applications

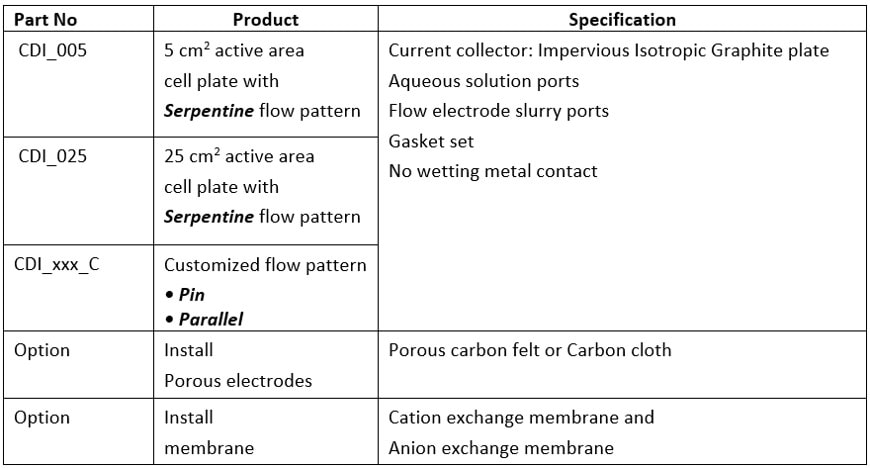

- Advance capacitive deionization (CDI) and flow-electrode capacitive deionization (FCDI) technology for water desalination application

- Management aqueous solution and electrode slurry

Accessories

|

Part Number

|

Product

|

Specification

|

|

Polymer electrolyte membrane

|

Nafion membrane

Cation exchange membrane (CEM) Anion exchange membrane (AEM) |

|

872-216-7641

|

Ecscell.com

|