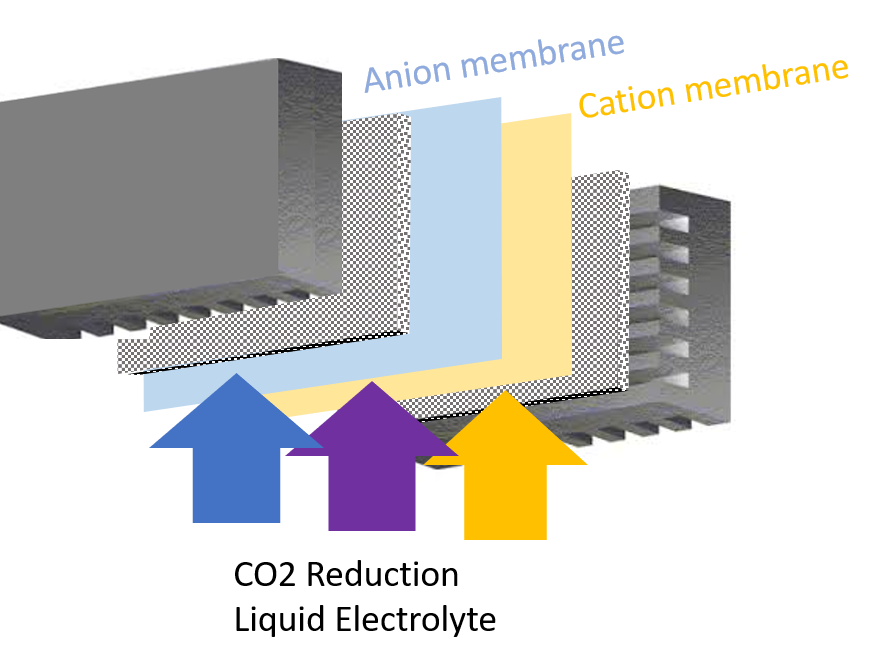

Electrolyzer - Testing PEM and Alkaline electroyzer and CO2 reduction

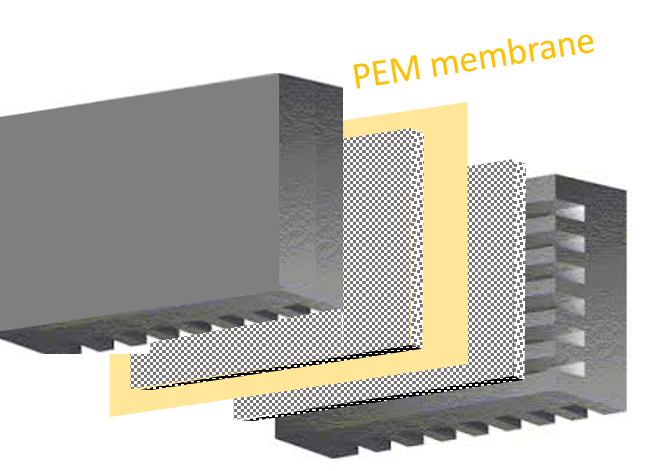

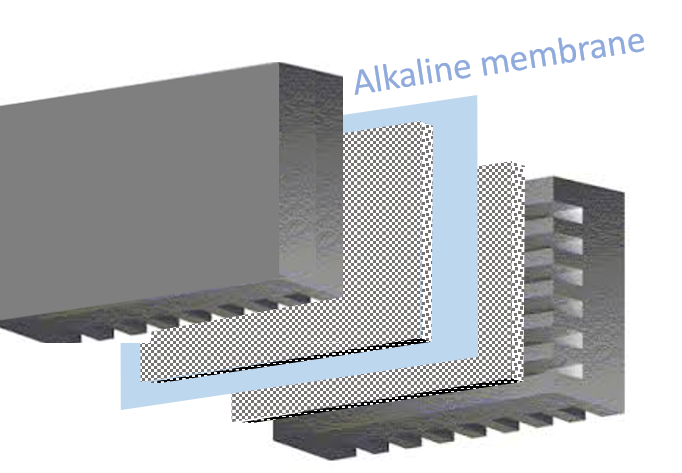

Electrolyzer is a process in which chemical change results from electron transfer reactions across the electrode/solution interfaces. A voltage applied between the two electrodes in an electrolytic cell drives these reactions. Ecscell electrolyzer is made of graphite/titanium plates for high temperature, high pressure and high voltage operation. Built-in reference electrode enables the study of contribution of voltage losses and polarization of anode and cathode electrodes to the overall reaction.

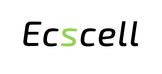

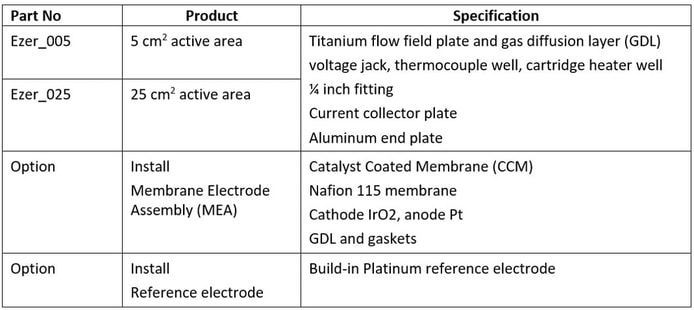

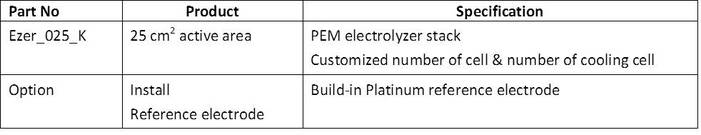

PEM Electrolyzer

Designed to allow the build of multi-cell stack and built-in cooling plate

Features

|

Applications

|

Accessories

|

Part Number

|

Product

|

Specification

|

|

Gas diffusion layer

|

Carbon paper and Titanium felt

|

|

Polymer Electrolyte Membrane

|

Nafion membrane

|

|

Membrane Electrode Assembly

|

Catalyst Coated Membrane (CCM)

Anode: Iridium Ruthenium Oxide Cathode: Platinum black |

|

Gasket

|

Precision flat gasket

|

|

872-216-7641

|

Ecscell.com

|