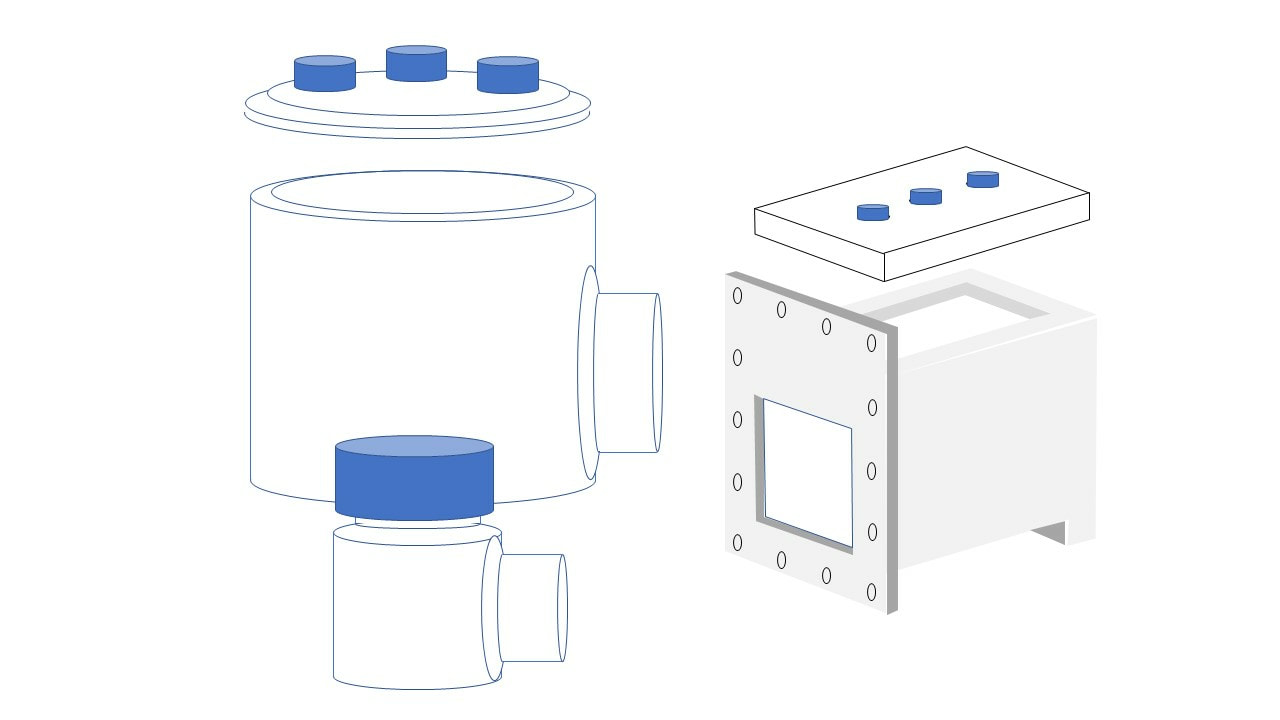

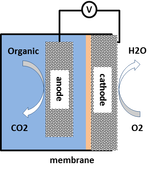

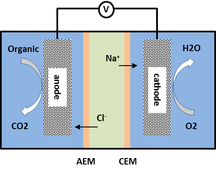

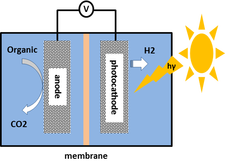

Ecscell microbial cells are designed to meet the demands of different aspects of microbial fuel cell-based technologies (MxCs). single, double, and three-chamber configurations and photoelectrochemical cell are available.

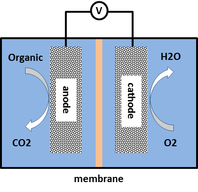

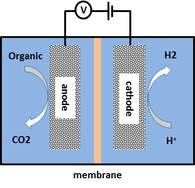

A Microbial Fuel Cell is a bioelectrochemical device that exploits metabolic activities of living microorganisms for generation of electric current or value-added applications beyond electricity generation, such as wastewater treatment, renewable hydrogen and implantable body devices.The usefulness and unique and exclusive architecture of this device has received wide attention of engineers and researchers of various disciplines such as microbiologists, chemical engineers, biotechnologists, environment engineers and mechanical engineers, and the subject of MFCs has thereby progressed as a well-developed technology. Coupling microbial metabolism with electrochemical reactions, Ecscell offers various functional and structural cell configurations to suit a variety of microbial fuel cell applications:

|

Microbial Fuel Cell

|

Available for single, double, and three-chamber configurations and photoelectrochemical cell

Features

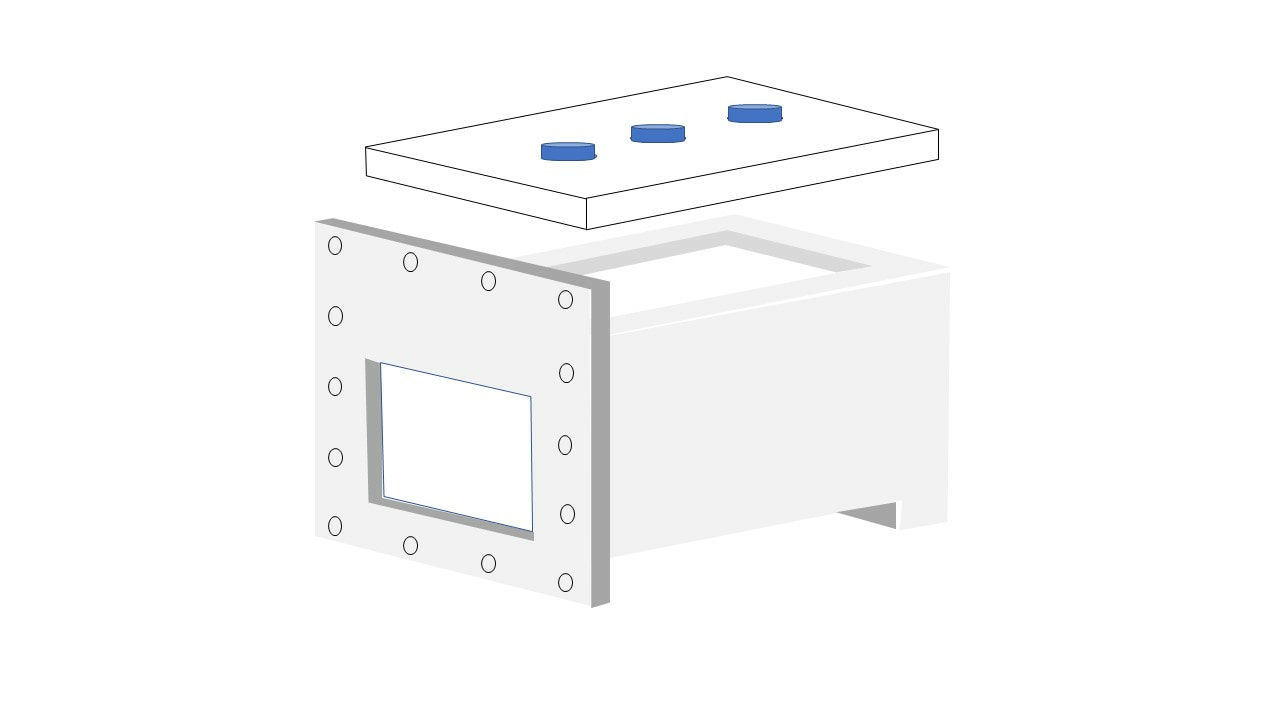

The MxC operational volume is 100-500 ml. It is equipped with 1 large bottle opening and 3 multi-purposed ports. These ports are used for reference electrode, gas purging, and filling solution, Gas purging maintains a high dissolved oxygen microbial fuel cell or performs deaeration. Quartz window for photoelectrochemical (PEC) cell available

|

Scientific glassware media bottles

|

Accessories

Electrode materials are considered in terms of surface area, electronic conductivity, chemical stability, cost and accessibility. Carbon-based materials are widely used because of their high conductivity, biocompatibility, chemical stability as well as low cost. Various membranes are available to improve synergy between membranes and microbial fuel cells

- Nafion Membrane - Proton (cation) exchange membrane, Ion exchange capacity 0.95-1.10 meq g-1

- Fumasep AEM - Anion exchange membrane, Ion exchange capacity 1.6-2.0 mmol g-1, 30 µm thickness

- Fumasep CEM - Cation exchange membrane, Ion exchange capacity 1.2-1.4 mmol g-1, 30 µm thickness

- Synthetic membrane - Track-etched membrane

- TORAY Carbon Paper - Plan electrode, Hydrophobic treatment (5-30% Teflon) or Hydrophilic treatment

- GDE_Gf Brush - Brush electrode, Carbon fiber brush (1” OD, 1” long), Twisted core made of titanium wire (2” long)

- MxC-REF - Reference electrode, Standard Calomel Reference Electrode (SCE) or Ag/AgCl Reference Electrode

- MxC-SPG - Sparger,maintains a high dissolved oxygen microbial fuel cell or performs deaeration

|

872-216-7641

|

Ecscell.com

|