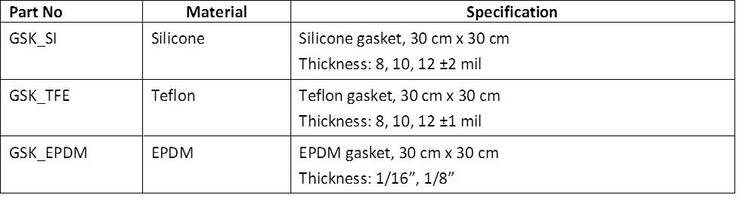

Gasket Seal

Critical of gasket thickness

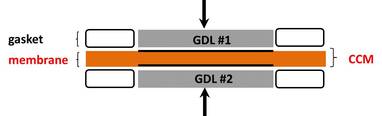

One of the important parameters in assembling a cell is the thickness of the gaskets. The gasket thickness determines how much the flow fields are allowed to pinch into the electrode. For a good contact achieving low contact resistance, it is essential that the ribs of the flow fields bit into the electrode providing good contact. Typical pinch values are 10-20 % compression of the electrode.

Gasket thickness = [(GDL#1 + GDL#2 + CMM) - (membrane)) x 80%]/2

1. “Effect of compression thickness on performance of gas diffusion layer of direct methanol fuel cells”, Yong-Sheen HwangHoon ChoiGu Young ChoYoon Ho LeeSuk-won Cha, nternational Journal of Precision Engineering and Manufacturing-Green Technology 1(2014)215.

2. “Influences of Contact Pressure on the Performances of Polymer Electrolyte Fuel Cells”, Prakash C. Ghosh, Journal of Energy 2013(2013). https://www.hindawi.com/journals/jen/2013/571389/

3. “Effect of Compression on the Water Management of a Proton Exchange Membrane Fuel Cell With Different Gas Diffusion Layers”, Zhongying Shi, Xia Wang, Laila Guessous, Journal of Fuel Cell Science and Technology 7(2010) 021012-7.

4. “The effects of compression and gas diffusion layers on the performance of a PEM fuel cell”, Woo-kum Lee, Chien-Hsien Ho, J.W. Van Zee, Mahesh Murthy, Journal of Power Sources 84(1999)45.

One of the important parameters in assembling a cell is the thickness of the gaskets. The gasket thickness determines how much the flow fields are allowed to pinch into the electrode. For a good contact achieving low contact resistance, it is essential that the ribs of the flow fields bit into the electrode providing good contact. Typical pinch values are 10-20 % compression of the electrode.

Gasket thickness = [(GDL#1 + GDL#2 + CMM) - (membrane)) x 80%]/2

1. “Effect of compression thickness on performance of gas diffusion layer of direct methanol fuel cells”, Yong-Sheen HwangHoon ChoiGu Young ChoYoon Ho LeeSuk-won Cha, nternational Journal of Precision Engineering and Manufacturing-Green Technology 1(2014)215.

2. “Influences of Contact Pressure on the Performances of Polymer Electrolyte Fuel Cells”, Prakash C. Ghosh, Journal of Energy 2013(2013). https://www.hindawi.com/journals/jen/2013/571389/

3. “Effect of Compression on the Water Management of a Proton Exchange Membrane Fuel Cell With Different Gas Diffusion Layers”, Zhongying Shi, Xia Wang, Laila Guessous, Journal of Fuel Cell Science and Technology 7(2010) 021012-7.

4. “The effects of compression and gas diffusion layers on the performance of a PEM fuel cell”, Woo-kum Lee, Chien-Hsien Ho, J.W. Van Zee, Mahesh Murthy, Journal of Power Sources 84(1999)45.

Importance of Gasket and Design

Gasket materials and designing the gaskets for proper sealing plays a crucial role in gas mixing and leakage. Gas mixing or crossover may result in a loss of cell performance as well as safety concern. Apart from sealing the gas leakage, it also prevents cracking the electrode substrate. In stack assembly, gaskets also help to cover the machining/dimensional variations of the components.

Gasket materials and designing the gaskets for proper sealing plays a crucial role in gas mixing and leakage. Gas mixing or crossover may result in a loss of cell performance as well as safety concern. Apart from sealing the gas leakage, it also prevents cracking the electrode substrate. In stack assembly, gaskets also help to cover the machining/dimensional variations of the components.