|

Currently there are three traditional liquid-electrolyte fuel cells: Alkaline (AFC),

Phosphoric (PAFC) utilizing liquid electrolytes KOH and H3PO4, and CO2 reduction cell. The electrolytes provide ionic conduction, reactant gas separation, and electrochemical kinetics. The electrolyte reservoir and distribution in operating fuel-cell electrochemically-active cell components (electrodes and electrolyte matrix) need to be carefully managed to achieve desired performance and life. |

|

The use of ionic liquids (IL) as electrolytes in electrochemical devices is an emerging field due to their high conductivity, as well as their thermal, chemical and electrochemical stability under anhydrous conditions. A benefit of using ionic liquids is that cells can be operated at temperatures above 100°C under anhydrous conditions because the proton transport is independent of the water.

|

|

Capacitive deionization (CDI) is a novel technology widely explored for water desalination applications. Advanced cell configurations and system designs with the implementation of ion exchange membranes and alternative concepts such as flow-electrode capacitive deionization (FCDI) with flowable electrode carbon electrodes exhibits continuous deionization and a high desalting efficiency.

|

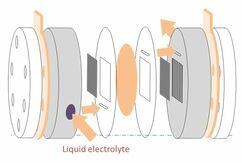

Ecscell offers liquid electrolyte cell hardware with access of electrolyte circulation.

Fuel Cell applying Liquid Electrolyte

Fuel Cell applying Liquid Electrolyte

Features

|

Applications

- Develop liquid electrolyte fuel cells: alkaline (AFC) and phosphoric (PAFC)

- Study novel Ionic liquid (IL) a promising electrolyte for fuel cells

- Management liquid electrolyte in fuel cells

- Advance capacitive deionization (CDI) technology for water desalination applications

Accessories

|

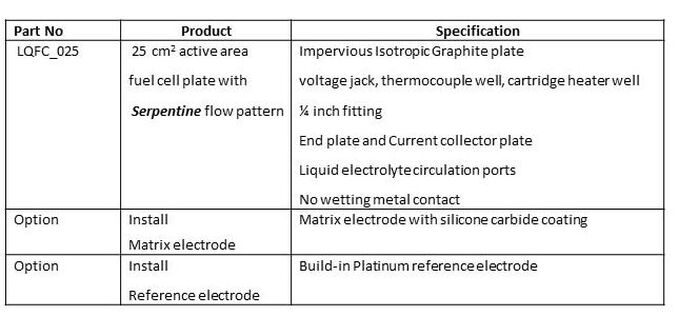

Part Number

|

Product

|

Specification

|

|

Electrodes and electrolyte matrix

|

Electrode with porous silicon carbide for carrying the liquid electrolyte

|

|

872-216-7641

|

Ecscell.com

|